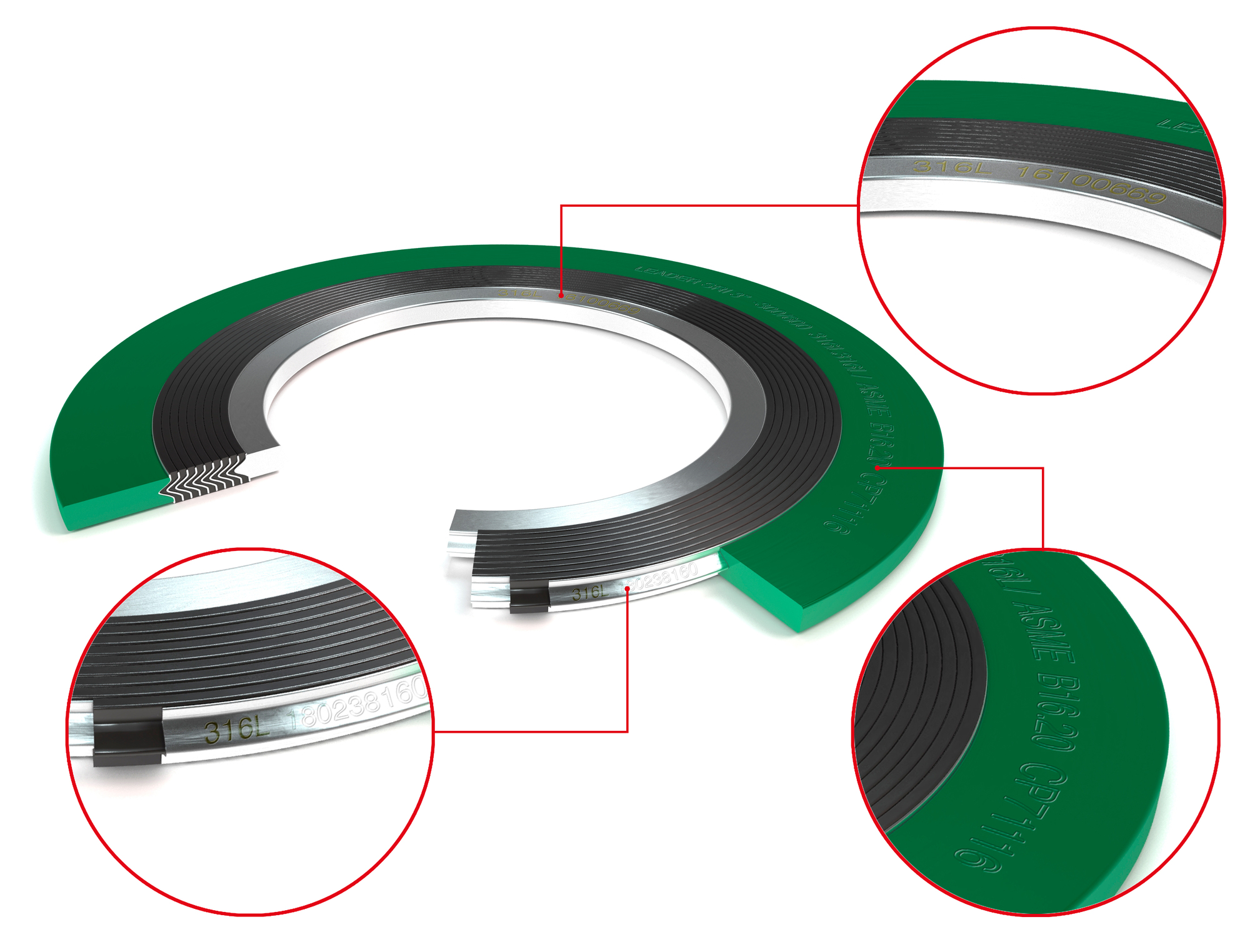

Spiral wound gaskets

Designed more than 100 years ago, Spiral Wound Gaskets (SWG’s) are widely used as high integrity and sustainable gaskets. The sealing element is manufactured from preformed, V-shaped metallic windings with intermediate soft sealing fillers. Most used filler materials are Graphite and PTFE or LeaderTHERM NXT 1000 (high temp. modified Phlogopite). Due to the gasket construction, SWG’s offer high compressibility and recovery. Applications are found in the (Petro-) Chemical Industry, Steam, On- and Offshore exploration, pipeline systems, pressure vessels and heat exchangers.

Low Stress / Low Density / High Density

All spiral wound gaskets can be produced with a Low-Stress winding. In this winding we use a slightly wider filler material than standard. This makes it possible to have a good seal where only a low surface pressure is available. Only for low pressure applications.

Another option is a low density winding or high density winding. This makes deformation under load easier, or harder, assuring a tight seal in your custom application.